Hot-dip galvanizing is the process of dipping fabricated steel into a kettle or vat containing molten zinc. The process is inherently simple which provides a distinct advantage over other corrosion protection method. While the steel is in the kettle, the iron in the steel metallurgically reacts with the molten zinc to form a tightly bonded alloy coating that provides superior protection to steel.

Applications:

- Steel Structures in Infra Structure sectors

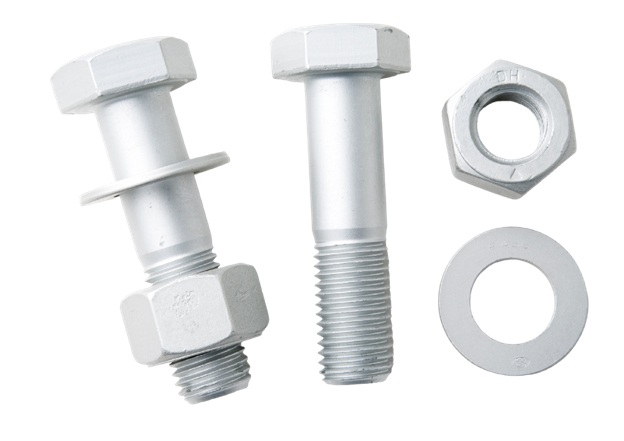

- Anchor Bolts

- Fasteners in Oil and Gas sector

- Gratings

- Electrical cable trays

- Steel pipes and other formed products.